SIDE GUSSET bag machines - Perfect packaging

for your product

The side gusset bag is the optimal packaging for dry products. In addition to its good dimensional stability, it offers the possibility of high-quality printing on up to 5 sides.

Optionally, the bags can also be equipped with additional features such as reclosables (Zipper, Aplix, Velcro, Flexico, Sunzip, Zippak, Elplast, Presto), easy opening, ventilation holes and many more.

B&B offers you several machine models to produce these bags efficiently. If desired, we can use different camera systems to help you produce high-quality bags and thus avoid possible customer complaints.

We will find the perfect variant for your product, feel free to contact us. In the meantime, we will inform you about possible side gusseted bag machines below.

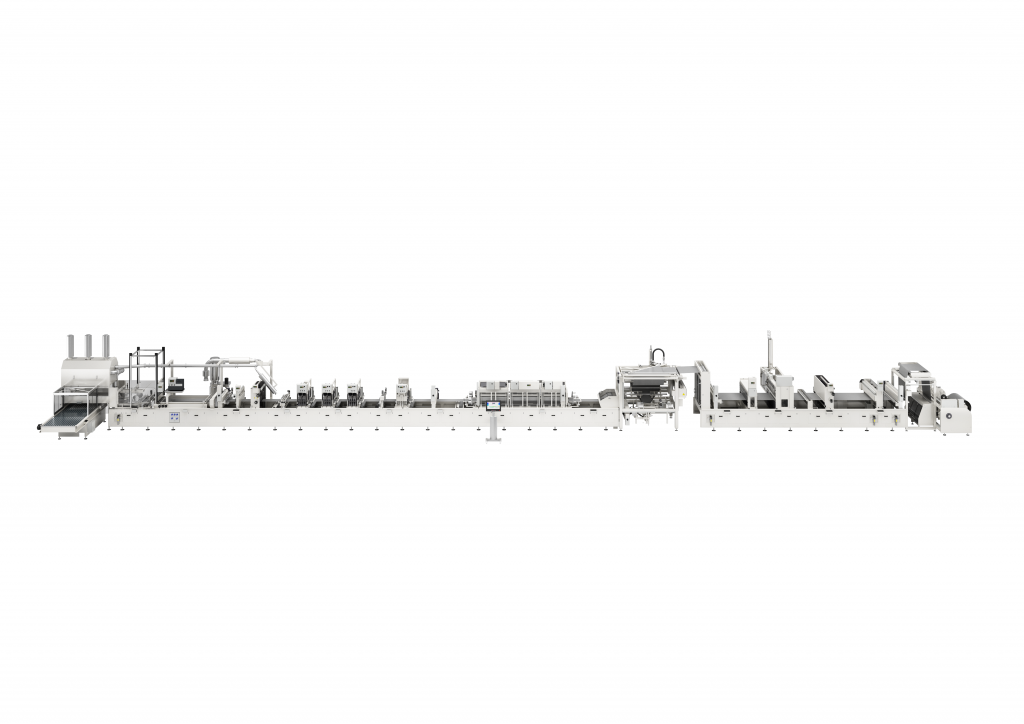

Side gusset bag making machine for easy MDO PE / PE processing for pet food bags

We team up with your experts to understand your manufacturing process from start to finish — homing in on the critical factors influencing your final product. Next, we create a tailormade machine solution based on our modular design dedicated to your needs.

Production capabilities

- Max bag dimensions 1000 mm x 450 mm x 200 mm

- 60 – 80 cycles / min

- 2 up possible

- Up to 1400 mm web width

- Longitudinal production process (possible)

MAXIMUM AUTOMATION

MAXIMUM AUTOMATION

RECIPE MANAGEMENT

RECIPE MANAGEMENT

MODULAR DESIGN

MODULAR DESIGN

PRODUCTION FROM ONE ROLL

PRODUCTION FROM ONE ROLL

MONO MATERIAL OPTIMIZED

MONO MATERIAL OPTIMIZED

ADVANCED PROCESS CONTROL

ADVANCED PROCESS CONTROL

INTUITIVE HMI

INTUITIVE HMI

+ MODULAR CUSTOMIZATION

+ MODULAR CUSTOMIZATION

KEY FEATURES

KEY FEATURES